Hygiene safety – the linchpin in food production

Hygienic safety does not just start with the question: How reliably can a food production system be cleaned? Even during the planning and construction of a system, it is crucial to select suitable, i.e. hygienic machines and components.

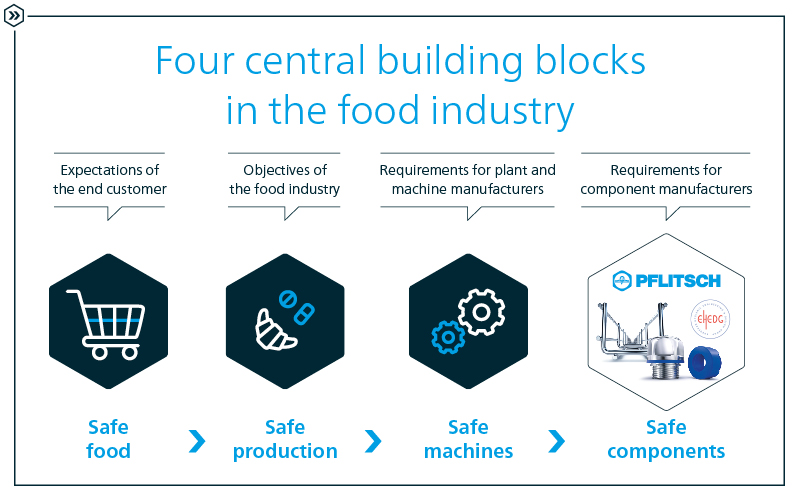

In this respect, it is not only the operators of food production plants who have a responsibility, but also plant manufacturers, designers and suppliers of machinery and components such as conveyor belts, video monitoring systems and sensors. Close dialogue between all parties involved is also necessary in order to clarify the respective requirements from the very beginning.

Food manufacturers and plant engineers are largely responsible for the hygiene safety of a production facility, as they set the course for the use of hygiene-compliant components. Close dialogue is essential here.

Hygienic Design in food production

Hygienic Design plays a central role for hygiene safety in the food and beverage industry. It is decisive for the selection of suitable materials and the design of components and production systems to be suitable for cleaning in order to avoid microbial and particulate contamination of products. Hygienic design guidelines are defined by the European Hygienic Engineering & Design Group (EHEDG).

PFLITSCH – your partner for hygienic cable management

The hygienic safety of a complex system is only as good as that of each individual component. This is why hygienic cable management is so important. As an expert in hygienic cable management and an active member of the EHEDG, we are familiar with the special challenges of Hygienic Design - and play a key role in driving the development of suitable solutions.

Thanks to our development expertise and many years of experience, we have built up a broad, holistic portfolio of Hygienic Design solutions that support seamless hygiene safety. We have the right solution for each of your applications - e.g. the new Cleanplus, the first and only hygienic cable gland certified according to the increased EHEDG requirements, and the tried-and-tested bluelobe CLEAN Plus cable gland, which is suitable for a wide range of hygienic applications with its high-temperature, explosion protection and EMC variants. High-quality solutions for cable routing and cable protection round off the programme.

Do you have questions about hygiene safety? We have the answers.

As a plant manufacturer for the food industry, are you faced with increasing hygiene requirements for cable management? As a component manufacturer, do you have a project enquiry with demanding hygiene requirements for the first time, but hygiene safety is giving you a headache? Do you operate a food production facility and want the right hygiene-compliant components to be used in your system?

If you have these or similar questions about hygiene safety in cable management, then we are the right contact for you. Please use the form below to contact us quickly and easily.