The new Floor Trunking from PFLITSCH –

the solution for production lines, not only in the automotive industry

When it goes beyond normal loads

The new PFLITSCH Floor Trunking is an innovative further development of the previous automotive trunking, specially designed for industrial environments with high demands on load-bearing capacity and slip resistance. The walkable trunking cover has been completely redesigned and no longer requires an aluminium channelled sheet. Instead, innovative embossing directly in the base material provides the necessary slip resistance and enables particularly economical production. As a walkable cable trunking, it complies with the factory standards of numerous automotive manufacturers and meets the high requirements of this industry. It is also used in highly automated production facilities, such as assembly lines, robot cells and machine parks, where it is valued as a tread-resistant Floor Trunking.

documentCreationDateTime: 2024-05-08

fileUploadDateTime: 2025-11-03

4.1 MB

EN

Flexibility and safety with every step

Based on just a few system components, the walk-on Floor Trunking is a flexible system that allows you to create your own cable routing quickly and easily. At the same time, you benefit from low ordering, storage, and assembly costs. The embossed cover ensures reliable slip resistance (R10 according to DIN 51130). With seven cross-sections with and without base perforation and universal partition walls, this robust cable trunking can be used very universally in indoor areas.

Your advantages at a glance

Walkable Floor Trunking with high footfall load

High strength, wide support spacing

Embossing in the cover with homogeneous stud arrangement for slip resistance/class R10 (DIN 51130)

Simple, fast and cost-effective installation

Compatibility with the PFLITSCH Industrial-Trunking system

Optional powder coating in RAL colours

2 mm sheet thickness for greater stability

The Floor Trunking is made of galvanised sheet steel with a material thickness of 2 mm for a perfect fit. This gives it exceptionally high stability. As a result, it can easily withstand footfall loads of up to 2,000 N and also allows installation with large support spacing, saving you time and money during assembly. With variable connecting straps, you can continuously adjust the walk-on duct for inclines between 90° and 180°.

Seven cross sections for a wide range of applications

The Floor Trunking is 100 mm high as standard. This means that when installed on the floor with 90 mm support feet, it remains below the 200 mm step dimension. Seven cross-sections from 100 mm to 600 mm in width are available as standard, with a choice of closed or perforated base:

- 100 mm

- 150 mm

- 200 mm

- 300 mm

- 400 mm

- 500 mm

- 600 mm

Different cables in one cable trunking

Separating walls can be positioned as required thanks to the optional, variable base perforation. This enables EMC-compliant separation into several flexibly adjustable chamber sizes, e.g. for power, control and data cables as well as for fluid and compressed air lines. The integration of PIK-Trunking with small cross-sections allows you to lay sensitive cables in their own closed internal duct.

Areas of application

The PFLITSCH Floor Trunking is versatile and meets the highest requirements for mechanical protection, load-bearing capacity and easy installation and maintenance. In highly automated production facilities, the walk-in duct provides protection and guidance for cables in assembly lines, robot cells and machine parks. The Floor Trunking enables orderly and safe installation of power and data cables, even in complex plant layouts. It also meets the special requirements of automotive production.

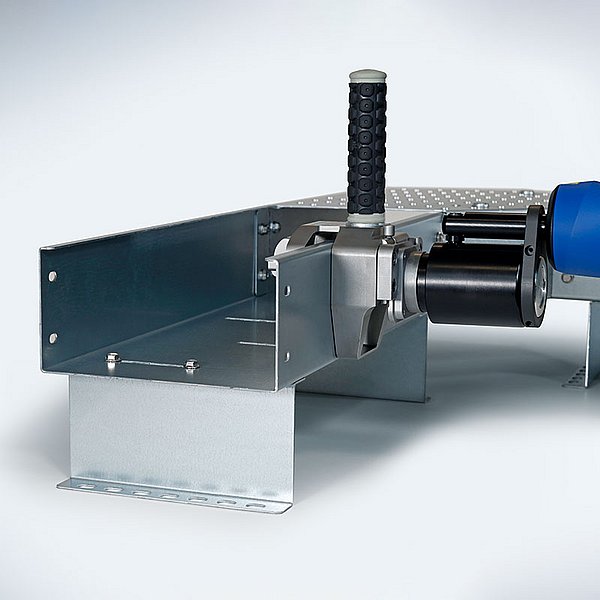

Tools

With the help of PFLITSCH tools, you can easily customise the sturdy Floor Trunking on site. With the appropriate notching tool, you can comfortably and efficiently notch side cut-outs in cable trunking bodies for feeding cables in or out. The hole punching tool, on the other hand, is useful for making connection holes in the body elements. There are also other small aids, such as the bolt turner/cover lifter and the combined open-end wrench/articulated socket wrench, which make everyday tasks easier.

Fastenings – a coordinated range

The walk-on duct is designed for floor mounting. For safe and easy installation on machines, in plants and industrial halls, we offer a range of high-quality fastenings that is constantly being expanded and is compatible not only with the Floor trunking but with all PFLITSCH cable trunking. This eliminates the need for expensive custom designs and minimises installation times. The high stability of the tried-and-tested fastening elements, combined with the outstanding robustness of the walk-on Floor trunking, allows for large support spacing, which helps you save installation time and costs.

Download

|

Brochure ‘PFLITSCH Floor Trunking’

New

heute - 60: 2025-10-13

documentCreationDateTime: 2025-10-31 fileUploadDateTime: 2025-10-31 |

10/31/25 |

Cable routing |

1.7 MB | EN | Download |

FAQ

The walkable cable trunking – previously also known as Automobile-Trunking – is the heavy-duty version of the PFLITSCH industrial duct. Made of galvanised sheet steel with a wall thickness of 2 mm, it is so robust that you can walk on it without any problems.

The Floor Trunking can withstand a footfall load of up to 2,000 N (approx. 200 kg).

You can lay a wide variety of cables and lines in the walk-in Floor Trunking: power, control and data cables as well as fluid and compressed air lines. By installing PIK-Trunking with small cross-sections, you can create closed internal ducts for laying particularly sensitive cables.

To assemble the Floor Trunking, you can use a range of fastenings that is suitable for all PFLITSCH cable trunking.

We recommend using the notching tool to make cut-outs in the trunking body and the hole punching tool to make connection holes in the trunking elements. The bolt turner/cover lifter and the combination open-ended spanner/articulated socket wrench make simple tasks easier.

The walk-in cable trunking is available in 7 sizes from 100 mm to 600 mm in width and 100 mm in height. We manufacture it exclusively in sheet steel with a wall thickness of 2 mm.

On request, the walk-in Floor Trunking is available with and without base perforation. The base perforation allows you to install partition walls or support feet and profiles.

The walk-in Floor Trunking is UL-certified and VDE-certified in accordance with DIN EN 50085-2-2 and thus meets all relevant international standards. This makes the Floor Trunking the safe choice for international projects as well.