EMC cable glands from PFLITSCH

Effective protection from electromagnetic interference

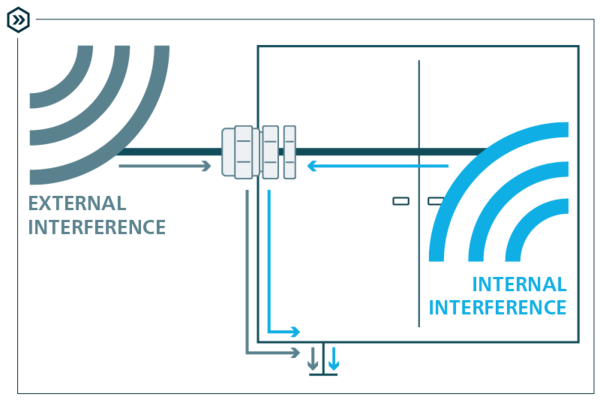

The rapid spread of electromagnetic radiation and the ever greater sensitivity of modern electronic components mean cable glands play an important role in a system’s screening concept. In everyday production scenarios, standard cable entries without sufficient EMC protection are still frequently used, even though they pose a significant safety risk.

You can eliminate this risk right from the outset – with EMC solutions from PFLITSCH. With its UNI Dicht and blueglobe series, PFLITSCH offers a scaled range of appropriate product solutions for EMC applications up to category 8.2.

documentCreationDateTime: 2024-05-08

fileUploadDateTime: 2025-02-14

11.5 MB

EN

The advantages of our EMC solutions

High screening attenuation values give your system reliable EMC screening

High current-carrying capacity for reliable discharge on enclosure

Reliable 360° cable shield contact

Suitable for a broad range of temperatures

Outstanding all-round properties such as tightness and strain relief

Time- and cost-saving installation

EMC cable glands for every application – including yours

There are hardly any limitations on the use of these cable glands. That’s why our solutions are designed for every application, no matter how unusual. Two factors are decisive for their quality and effectiveness: the attenuation values and the current-carrying capacity.

Screening attenuation

Outstanding attenuation values are required wherever interference signals resulting from electromagnetic coupling can impair the transmission of sensitive data and such data must be protected, e.g. in the fields of measurement and radar technology, drivetrain and control technology, and telecommunications.

The electrical screening effect of EMC cable glands is essentially determined by the following properties:

-

Conductivity of the material surfaces

-

Transitional impedance between cable shield and/or contact element

-

Transitional impedance between contact element and/or cable gland body

-

Transitional impedance between cable gland body and/or housing

Current-carrying capacity

A high current-carrying capacity is necessary if high current levels flow through the shielding braid of the cable and they are to be reliably discharged at the machine enclosure. Types without sufficient current-carrying capacity can easily overheat and become damaged, which then also means that the screening effect is no longer guaranteed. Particularly in the field of e-mobility – especially in high-voltage vehicle systems – the current-carrying capacity is extremely important. With PFLITSCH EMC cable glands, which have been specially developed for the electric mobility industry, you are always on the safe side.

Which cable gland should be used for EMC applications?

Effective protection against electromagnetic radiation

Why is protection against electromagnetic interference fields in machines and systems becoming increasingly important? What is the difference between conical and spring contacting in EMC cable glands?

The quality of the shield contact is decisive for the effectiveness of an EMC cable gland when it comes to screening attenuation and current-carrying capacity. PFLITSCH resorts to different design principles in its models to ensure reliable and durable shield bonding, depending on the application and its requirements. In this video, PFLITSCH Product Manager Raphael Brandt explains the most important aspects to you in a simple and clear way. You will also learn which customer benefits make PFLITSCH solutions the first choice in terms of EMC safety and what distinguishes our latest EMC product development: the UNI Dicht TRI.

Note: Please turn on the subtitles for the linked YouTube video and set them to English.

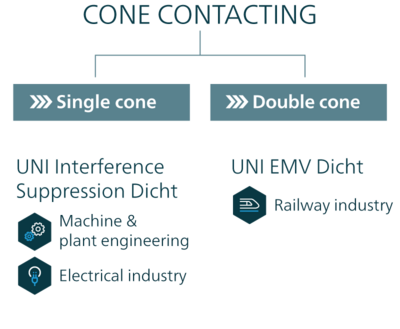

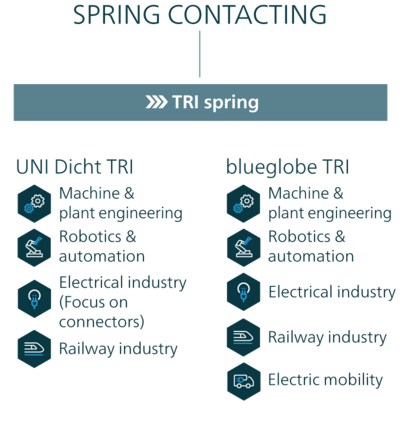

Two design principles: cone and spring contacting

Two functional principles, which differ fundamentally in terms of their design and effect, exist for achieving reliable contact between the cable gland and the cable shield, namely cone and spring contacting. To help you understand how each of them works in practice, let’s take a closer look at the two methods.

Cone contacting

A distinction needs to be made here between single and double cones. If a single cone made of brass is used, the stripped end of the shielding braid is first of all pushed onto it and then compressed by tightening the pressure screw to achieve a reliable shield bond.

In contrast to this, with double cones, the end of the stripped shield braiding is first pushed onto one cone and then clamped with the aid of the second cone. By tightening the pressure screw, you create an exceptionally secure and reliable bond that is also extremely resistant to vibration. With both cone contacting methods, the cable shield ends in the cable gland.

Spring contacting

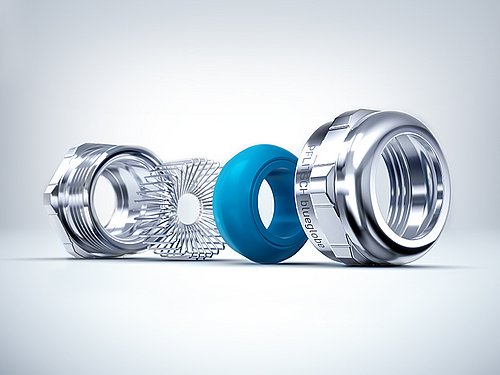

For stainless-steel and bronze shield contacting, PFLITSCH relies on its patented, in house-developed TRI spring, which is named after its triangular profile. This special design principle facilitates large-area and secure 360° contact with the cable shield and is the key to its unrivalled characteristics. Above all, these are its above-average screening attenuation properties – even in the upper frequency range –, its unusually high current-carrying capacity and its extremely high resistance to sustained vibration.

Another benefit: as part of the easy, time- and cost-saving installation process, the cable sheath is stripped only at the contact point, so that the shield runs from end to end and does not have to be separated. The TRI spring makes it easy to correct the cable.

Our EMC solutions

To ensure you are equipped to handle all conceivable EMC-related tasks, PFLITSCH offers you a perfectly coordinated range of EMC cable glands that is second to none. Based on the blueglobe product line and the UNI Dicht modular system, we provide you with the right EMC solution for every application, no matter how individual it may be, which differs from each of the others in their its specific EMC properties. What all of these solutions have in common are basic properties such as tightness, strain relief and time- and cost-saving installation – and of course the proven PFLITSCH quality. The complete range includes products for universal applications, sophisticated hygiene applications and highly developed solutions for the electric mobility sector.

Our TRI spring principle is revolutionary: what makes it unique is the mechanical separation between strain relief and tightness on the one hand and screening on the other. Reliable and durable bonding with the cable shield is consequently possible over a large area. The TRI spring also lays the foundation for the surprisingly simple design of the gland body as well as for its compact dimensions.

UNI Dicht TRI

- UNI Dicht TRI cable gland – compact solutions individually assembled from the UNI Dicht modular system, enabling high EMC screening attenuation where installation space is limited

- Durable and low-impedance 360° contact with the cable shield over a large area thanks to the patented triangular spring with its exceptional attenuation properties

› Also in the upper frequency range

› Even with non-round and off-centre cables

› Even when subject to vibration - Very high current-carrying capacity for reliable discharge of undesirably high shield currents

- Great economy thanks to simple, fast and reliable installation that saves time and costs

- Having to strip the cable sheath only at the actual contact point means shielding can be continued uninterrupted

- TRI spring makes it possible to easily correct the positioning of the cable during installation

- Mechanical separation between strain relief and screening

- Large screening and sealing range can be covered with just one cable gland size: suitable for use with plugs in combination with small cable diameters. (The M25 gland offers a screening range from 3 mm to 16 mm)

- Anti-twist protection for the cable when the pressure screw is tightened

- UL certificate pending

The UNI Dicht Multiple TRI variant is the only EMC solution available on the market for feeding in multiple shielded cables. It guarantees maximum safety owing to the reliable bonding between the individual cable shields using a separate triangular spring.

blueglobe TRI

- blueglobe TRI cable gland – the all-round solution for the highest individual EMC requirements

- Durable and low-impedance 360° contact with the cable shield over a large area thanks to the patented triangular spring with its exceptional attenuation properties

› Also in the upper frequency range

› Even with non-round and off-centre cables

› Even when subject to vibration - Very high current-carrying capacity for reliable discharge of undesirably high shield currents

- Great economy thanks to simple, fast and reliable installation that saves time and costs

- Having to strip the cable sheath only at the actual contact point means shielding can be continued uninterrupted

- TRI spring makes it possible to easily correct the positioning of the cable during installation

- Large screening and sealing range can be covered with just one cable gland size

- Certified in accordance with fire protection standard EN 45545

Specialised EMC solutions

Are you looking for specific products for unusual applications for which you cannot find conventional solutions? Here, too, we have innovative and installation-friendly products on offer that help you save time and money because the alternative would only be a far more elaborate solution or a complex installation. The range also includes the only EMC solution available on the market that can seal several shielded cables and make EMC-safe contact. If you need to upgrade from a standard to an EMC cable gland, use our EMC adapter.

Unrivalled – simple and reliable assembly

The effort required to assemble a conventional EMC cable gland depends on its structure. A careful approach is called for, which tends to be relatively time-consuming. PFLITSCH offers a more user-friendly route. Our EMC variants with TRI spring bonding are extremely simple to assemble – leading to time and cost savings coupled with maximum dependability. The cable sheathing only needs to be stripped at the contact point. Once the braiding has been removed, the cable can be pushed through the cable gland without difficulty. The triangular spring immediately wraps itself securely around the braid and establishes durable 360° contact over a large area. The design of the TRI spring prevents it from becoming caught in the braiding during assembly or disassembly.

Another advantage is that because the cable sheath only has to be stripped at the contact point, the shielding can be continued uninterrupted and the positioning of the cable can be easily corrected during installation.

Application areas

- Electric mobility

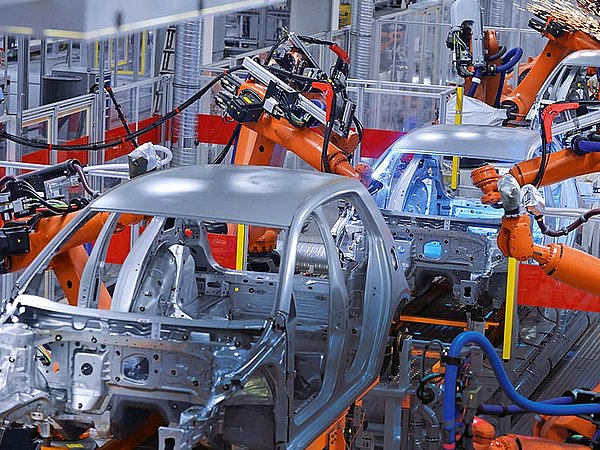

- Automation and robotics

- Railway industry

- Chemical, oil and gas industries

- Electrical industry

- Food and pharmaceutical industries

- Mechanical and plant engineering

- Telecommunications

Technical data

- Material: brass, nickel-plated and various stainless steels

- Temperature range: –40 °C to +130 °C (series) or –55 °C to +200 °C (silicone)

- Type of protection: IP 68 (up to 15 bar) and IP 69

- Thread: metric and Pg

- Connection sizes: metric from M10 to M85 and Pg 7 up to Pg 48

Examples of use

Railway industry

In rail vehicles, components such as cable glands must have a whole range of sophisticated properties. These include fire protection suitability, tightness, vibration resistance, mechanical protection (e.g. from stone impact) and weather resistance. Furthermore, reliable screening attenuation is essential for certain applications. This is provided by safe EMC solutions from PFLITSCH: For example, the UNI EMC Dicht fire protection cable gland is used in rail traction motors in the driven rotary points in the underfloor area. And the blueglobe TRI fire protection cable gland is used for voltage and frequency converters in the carriage roof or underfloor area for the electrical supply of components and power and data cable entry. However, our EMC solutions can also make an important contribution to safe mobility in the provision of phone and internet mobile data on trains and the use of modern passenger information systems.

Automation and robotics

Automatic production processes are becoming increasingly sensitive to electromagnetic interference. The reason: the progressive automation, digitalisation and miniaturisation of components as well as the increasing use of electronic devices, which means that EMC security is therefore becoming more and more important. If an electromagnetic disturbance occurs and interrupts operations, the damage is incalculable. The solution: Due to their high screening attenuation, PFLITSCH EMC cable glands enable electromagnetic interferences from the cable shield to be reliably discharged from equipment enclosures and thus kept away from the production process.

Wind farms

Wind farms are subject to continual checks and supervision. Their data and processes are all constantly recorded, collected and distributed. Not only do large volumes of data need to be transmitted, they also need to cover long distances. Up to 160 m between the nacelle and the base of the tower need to be bridged. If data cables are used, the signals can be impaired by electromagnetic interference. To solve this problem, PFLITSCH has developed EMC cable glands with bending protection suitable for data connectors in order to meet all the data communication requirements.

Test standard

PFLITSCH cable glands feature a high level of screening attenuation. Screening attenuation is a measure of shield quality in terms of electromagnetic compatibility. This property also plays a key role when selecting the right EMC cable gland. PFLITSCH has developed a measuring method for determining the quality of the screening effect by calculating the frequency-dependent voltage drop across the cable gland. Our KoKeT (Koaxial Kelvin Tube) procedure allows measurements in accordance with IEC 62153-4-10 on screened cable glands up to size M85.

For international use, the two PFLITSCH cable glands meet international standards that include VDE, UL, CSA, DNV and EAC. They also safely and reliably meet the worldwide ATEX standards.

Cat 8.2 suitability thanks to TRI spring

The blueglobe TRI is the only solution in the market where a Cat 8.2 cable entry complies with the limits laid down by IEC 61156-9 Ed.1.0 up to a frequency of 2 GHz. Cat 8.2 data cables are especially common in computer centres, where they achieve transmission speeds of up to 40 gigabits per second and a transmission frequency of 2 GHz. Our TRI spring passed the Cat 8.2 test – renewed confirmation of its superior EMC properties, even in the most demanding applications.

Downloads

|

Product information UNI Dicht TRI

heute - 60: 2025-05-02

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2023-08-07 |

08/07/23 |

Cable gland |

489.2 KB | EN | Download | ||

|

Competence brochure EMC

heute - 60: 2025-05-02

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2024-07-30 |

07/30/24 |

Industries |

2.6 MB | EN | Order as Print | Download | |

|

Flyer Naval cable gland blueglobe TRI NM/Cr

New

heute - 60: 2025-05-02

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2025-05-23 |

05/23/25 |

Cable gland |

1.8 MB | EN | Download | ||

|

Product information KoKeT

heute - 60: 2025-05-02

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2021-02-22 |

02/22/21 |

Cable gland |

2.1 MB | EN | Download | ||

|

Assembly instruction blueglobe EMC selective

heute - 60: 2025-05-02

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2017-01-16 |

01/16/17 |

Cable gland |

802.1 KB | EN | Download | ||

|

Assembly instruction blueglobe TRI CLEAN Plus

heute - 60: 2025-05-02

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2019-07-22 |

07/22/19 |

Cable gland |

2.2 MB | EN | Download | ||

|

Assembly instruction blueglobe TRI

heute - 60: 2025-05-02

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2025-04-23 |

04/23/25 |

Cable gland |

762.7 KB | EN | Download | ||

|

Assembly instruction UNI Dicht TRI

heute - 60: 2025-05-02

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2024-05-06 |

05/06/24 |

Cable gland |

4.7 MB | EN | Download |

Product portfolio EMC cable glands

Further information

Cable trunking

You’re also interested in the multitude of possibilities offered by our cable trunking solutions? Or are you looking for a concrete solution to a specific cable laying project? The Cable Trunking section provides an overview of all of our models and highlights their specific advantages and benefits.

Cable routing

Downloads

Are you looking for a comprehensive overview of PFLITSCH’s products and services? You can find the latest PFLITSCH catalogues and brochures in the Downloads section (PDF files).

Contact

You have questions about a product, would like to make an appointment for a one-to-one consultation or would like to experience our products live? Get in touch! We look forward to hearing from you.

Contact