The UNI Dicht modular system from PFLITSCH – as versatile as your requirements.

It’s in your hands – the right solution for your needs

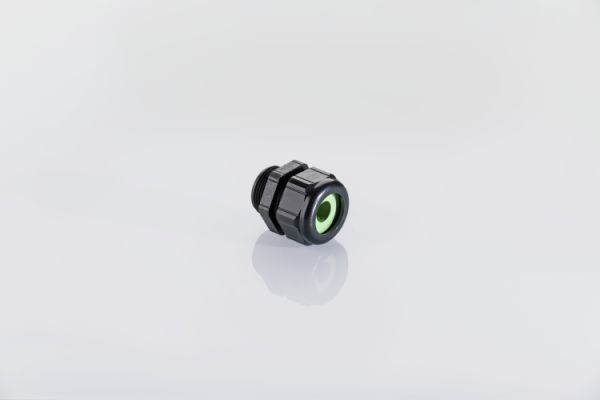

With its diverse range of variants the PFLITSCH UNI Dicht cable gland system leaves nothing to be desired when it comes to meeting international requirements for industrial cable glands. Whether solutions for EMC or explosion protection, multiple elbow and flange glands or combinations with corrugated tubes and protective conduits for safe, reliable cable protection – UNI Dicht cable glands have a practically unlimited range of applications. Simply put together your individual, application-specific cable gland and choose from a wide range of specific criteria such as connection thread, bending protection, increased strain relief, elbow glands, flat cable sealing, etc.

documentCreationDateTime: 2024-05-08

fileUploadDateTime: 2024-08-28

13.4 MB

EN

The key advantages of the UNI Dicht system at a glance

6,000 single components for 20,000 application-specific cable glands

Metal and plastic variants

M4 to M120 and Pg 7 to Pg 48 as well as NPT, CTG or inch threads

Type of protection IP 68 (10 bar) and up to IP 69

EMC, ATEX, hose, corrugated tube and elbow glands

Reduced and expanded designs

Cable gland bodies – materials and threads

The UNI Dicht cable gland consists of a gland body and a corresponding sealing insert. The cable gland bodies are available in the metals brass, zinc, stainless steel and aluminium as well as the plastics PVDF and polycarbonate. PFLITSCH also offers cable gland bodies with a variety of different threads:

- Metric thread

- Pg connection thread (armoured thread with 80° flank angle)

- Conical NPT (National Pipe Thread – US standard thread)

- Cylindrical Whitworth inch thread (the first standardised thread in inches worldwide)

Sealing inserts – also for non-standard customer requirements

We manufacture the sealing inserts for the UNI Dicht system from the high-quality materials TPE, TPE-V and silicone, which are resistant to chemicals, improve strain relief and meet high ingress protection ratings up to IP 68 (10 bar) and IP 69 as standard. At the customer’s request we also manufacture application-specific sealing inserts. Our in-house manufacturing method also enables us to produce prototypes and small batches at affordable prices. You also have the option to punch perforations in closed sealing inserts yourself. Besides the round perforations, we also produce variants for a range of flat or non-standard cables, for example for the ASi bus.

The UNI Dicht modular system

Inserting multiple cables reliably through one hole

For reasons of space or better handling, you may want to feed multiple cables reliably through a hole in an enclosure. All you need to do is replace the standard UNI Dicht gland with other types from the UNI Multiple range, which offers a variety of hole patterns so that a wide range of cable diameters can be sealed.

Sealing inserts for pre-assembled cables

The multiple-cable sealing inserts are also available as splittable versions, which makes them capable of sealing cables that are pre-assembled with connectors or sensors. First, feed these components through the gland body before the cables are reliably enclosed by the two halves of the sealing insert. We also offer the sealing inserts with lateral slots for the same application, as you can easily insert cables through the slot that is open to the outside.

For greater strain relief and bending protection

The UNI Dicht series offers a whole range of tailored solutions especially designed for high strain relief and optimum bending protection requirements:

Increased strain relief included

PFLITSCH cable glands are already capable of strain relief ratings that meet EN 62444 class A standards. The UNI Dicht Strain Relief Cable Gland, UNI Clamping Dicht and UNI Bending Strain Relief Cable Gland series from the UNI Dicht modular system provide even more safety through increased strain relief.

UNI Bending Stain Relief Cable Gland protection cable glands

With these cable glands, a long, conical bending protection grommet made of TPE prevents the cables from being damaged at the bending point. The grommet fits tightly around the cable and also protects the section under bending stress from outside influences such as UV radiation and aggressive media. For easier installation, the grommet can be widened to make it easier to push the cable through.

UNI Dicht Strain Relief Cable Gland with integrated jaws

The sealing inserts of the UNI Dicht Strain Relief Cable Gland are made of TPE and TPE-V with integrated clamps made of PA, which act like a jaw chuck and absorb tensile forces of up to over 200 N on the cable, making it vibration-proof.

UNI Flex Dicht for even better bending protection

The UNI Flex Dicht uses a specially coiled stainless steel spring with a progressive characteristic curve to optimise the distribution of bending stresses on the cable. Over a length of about 10 cm, this cable gland reliably absorbs even heavy dynamic bending stresses at the cable entry.

UNI Clamping Dicht with bracket clamps

The two bracket clamps on the pressure screw of the UNI Clamping Dicht enable you to reliably fix cables, absorbing tensile forces of over 500 N. The UNI Clamping Dicht therefore meets the “B-version” required by the EN 62444 standard.

UNI Bending Strain Relief Cable Gland – the perfect combination

The UNI Bending Strain Relief Cable Gland is a useful variant. Its sealing insert is fitted with clamping jaws for vibration-proof strain relief and also has a large moulded grommet that reliably protects the cable from kinking, for example in industrial connectors.

Selected UNI Dicht products

Download

|

Customer case study Cloos (UNI Dicht M4)

heute - 60: 2025-05-02

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2019-07-19 |

07/19/19 |

Industries |

2.8 MB | EN | Download | ||

|

Customer case study Lenord and Bauer (UNI Dicht)

heute - 60: 2025-05-02

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2019-07-19 |

07/19/19 |

Industries |

2.4 MB | EN | Download | ||

|

Customer case study Koch (UNI Dicht)

heute - 60: 2025-05-02

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2019-07-19 |

07/19/19 |

Industries |

2.2 MB | EN | Download |