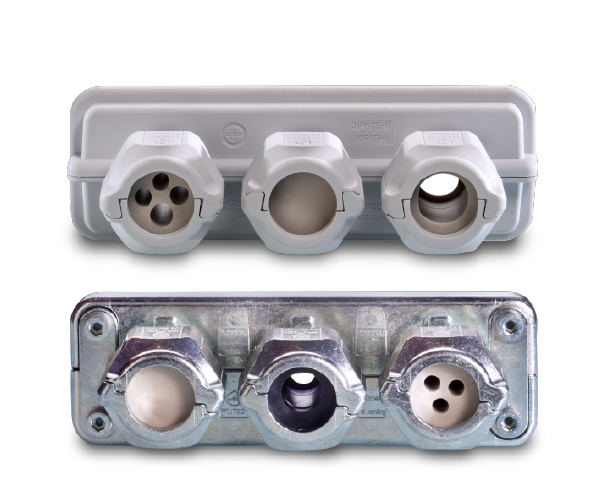

PFLITSCH UNI flange –

the splittable flange for feeding pre-assembled cables

The ideal framework for optimum sealing performance

Secure entry of pre-assembled cables into machines and control cabinets can be a daunting challenge – but it doesn’t have to. PFLITSCH’s splittable UNI flange is a well-designed solution that serves this purpose perfectly.

The UNI flange’s two-piece frame plate fits simply into 112 mm x 36 mm panel cut-outs for 24-pin rectangular plug connectors, allowing pre-assembled cables to be fed in and provided with a reliable seal.

The best of both worlds: cable gland and flange solution in one

The UNI flange is the only splittable flange solution based on the sealing principle of a cable gland. The properties of the UNI Dicht system are combined with the advantages of a splittable frame plate and splittable pressure screws.

documentCreationDateTime: 2022-01-04

fileUploadDateTime: 2019-03-26

1,009.1 KB

Your advantages

Secure and convenient entry of pre-assembled cables

Three integrated cable glands for over 100 different sealing inserts

For cable cross-sections from 2.0 mm to 20.5 mm, including flat or special cables

Type of protection IP 66, Type 4 or 4X

Above-average strain relief values according to EN 62444 class A

Ambient temperatures from –20 °C to +80 °C

Types and materials

UNI flange

Material: grey or black PA

Thread: metric

Three integrated splittable cable glands

Dimensions: 149.6 mm wide x 51.6 mm high

Spanner width: SW x E 35 x 38.6 mm

Sealing inserts: TPE-V, T80

Sealing insert size: M25

Cable cross-sections: 2.0 mm to 20.5 mm

Type of protection: IP 66, Type 4X

Temperature range: –20 °C to +80 °C

UNI flange HD (heavy duty)

Material: die-cast zinc for use in harsh industrial environments

Thread: metric

Three integrated, splittable cable glands

Dimensions: 149 mm wide x 50 mm high

Spanner width: SW x E 36 x 40 mm Sealing inserts: TPE-V, T80s

Sealing insert size: M25

Cable cross-sections: 2.0 mm to 20.5 mm

Type of protection: IP 66, Type 4

Temperature range: –20 °C to +80 °C

Three integrated cable glands for over 100 sealing inserts

The frame plates of the UNI flange variants come pre-drilled with through-holes to allow secure bolting. The PA version is also available with threaded inserts for full contact protection in accordance with Class II (DIN EN 61140, VDE 0140-1). Over a hundred different sealing inserts belonging to the UNI Dicht system can be fitted into the three double nipples integrated in the splittable frame plates. The grooves in these double nipples and on the inserts prevent the sealing insert and the cable from turning as the pressure screw is tightened.

High strain relief and reliable sealing performance

Soft pressing – the UNI Dicht system’s sealing principle – prevents constriction of the cable from causing serious damage to the sheath. It also enables high strain relief according to EN 62444 Class A. The sealing inserts and the circumferential seal on the frame plate prevent the ingress of dust and water jets in line with the IP 66 protection rating and Type 4 or Type 4X.

Accessories

Slit sealing inserts: from standard to multiple

When feeding pre-assembled cables, slit sealing inserts are necessary in order to get the full benefit from the UNI flange’s split design. The overall concept for these products is based on full splittability and the slit sealing inserts are an essential part of it. As an additional advantage, the multiple sealing inserts make it possible to insert multiple pre-assembled cables within a minimum of space, even those with varying thicknesses.

Sealing inserts for flat or special cables

Our portfolio also includes sealing inserts for flat or special cables. These inserts can be supplied in either TPE-V or fire-resistant TPE (T80). Closed sealing inserts are likewise available. Moreover, we offer the “punching as required” principle: Simply state the desired hole pattern and we will drill it for you in the corresponding closed sealing insert. Alternatively, users can make the holes themselves with special drills. Any holes not used in a multiple sealing insert can be sealed with blanks.

Assembly

Fewer components – simple assembly

The two halves of the frame are placed around the cable being fed through the cut-out in the enclosure, hooked together and fastened in place. You can then position the cables in the slit sealing inserts, for example using the handy PFLITSCH expanding pliers, and push them into the double nipples of the frame plate. Then place the two parts of the pressure screw around the cable, clip them together and screw them onto the double nipple.

Download assembly instructions for UNI flange with through-holes

Download assembly instructions for UNI flange with threaded inserts