PFLITSCH fire protection cable glands for the railway industry

Certified safety for rail vehicles

Which properties does a fire protection cable gland need to have?

When it comes to fire protection in trains, two criteria are essential.

Firstly, there is the need to minimise the spread of fire and smoke. In other words, a cable gland must contribute towards minimising the probability of fire outbreak and limiting the spread of fire. Therefore, fire may not be able penetrate the cable gland.

Secondly, it may only release a minimum of harmful smoke and gases in the event of a fire.

documentCreationDateTime: 2024-05-08

fileUploadDateTime: 2025-07-09

2.5 MB

EN

Your advantages at a glance

Cable glands for the railway industry that are certified in accordance with international fire protection standards

Excellent tightness of seal in accordance with protection classes IP 68 and IP 69 and above-average strain relief

Cable glands for interior and exterior use that are highly weatherproof

Protection from mechanical wear such as stone chipping and vibrations

Time- and cost-saving installation

Above-average durability and low total costs across the overall life cycle

Why is fire protection so important in the railway industry?

The topic of fire protection plays a crucial role in the field of railway technology because it is all about ensuring that passengers are transported in a safe manner. In hazardous situations, especially in the event of a fire, all the components installed must reliably contribute to the safety concept. The ultimate aim is for rail vehicles to remain operational for at least 15 minutes in order for a train to safely pass extended underground sections of track before being evacuated.

PFLITSCH fire protection cable glands – tested and certified

As a manufacturer of components and/or systems, you are responsible for their faultless functioning – and as a railway sector manufacturer you are required to transport passengers and goods in a safe manner. You can trust PFLITSCH’s state-of-the-art fire protection cable glands for installation in new vehicles as well as for repair work. They meet the diverse and stringent requirements of the international railway industry and guarantee you an outstanding level of reliability. PFLITSCH solutions are continually tested and certified in accordance with current standards and ideally suited for unrestricted use in trains – whether on open lines, in tunnels or at stations – giving you the good feeling of always being on the safe side.

Typical areas of application on the train

Chassis near axles and rails

Routing of power and data cables

Small systems in the driver’s cab

Air-conditioning units

Pantographs

Carriage transitions

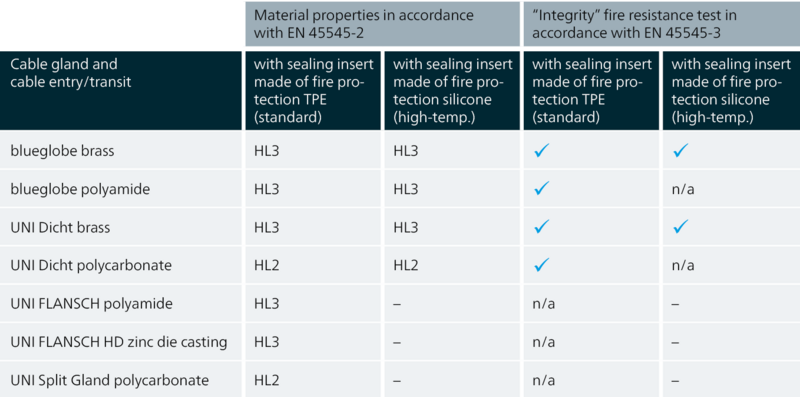

Standardised fire protection in accordance with EN 45545

The EN 45545 standard was introduced at European level to standardise fire protection in rail vehicles. The standard replaces a variety of national rules, such as DIN 5510-2 in Germany, and stipulates a high degree of fire protection for rail vehicles, stations and tunnels throughout Europe. In order to take every aspect of a comprehensive and effective fire protection standard into account, 45545 includes the EN 45545-2 fire behaviour test and the EN 45545-3 fire barrier test, which apply to both cable glands and other components.

Certifications and association- and manufacturer-specific tests

Good examples of established fire protection standards are the tests required by the NFPA and the vehicle manufacturer Bombardier, which PFLITSCH fire protection cable glands have successfully passed with flying colours.

- International certificates: VDE, CSA and UL

- NFPA 130 (National Fire Protection Association US)

Components are subject to testing for flammability, smoke density and smoke release rates - Bombardier SMP 800-C

Here, the material behaviour and the development of toxic material emissions from the sealing inserts in the event of fire are tested.

PFLITSCH fire protection solutions

PFLITSCH products are manufactured in a broad range of variants, particularly for reasons of fire protection, as a number of different product ranges can be used in transportation technology, depending on requirements.

Corrugated conduit transit

The corrugated conduit cable gland is the perfect solution if you need to feed corrugated conduits into and out of rail vehicles through walls or roofs and then run them further through the vehicle. The gland is based on the UNI Dicht system and has special corrugated conduit sealing inserts that meet the highest fire protection requirements.

blueglobe fire protection cable gland

The varying designs of blueglobe fire protection cable glands enable them to be used in a diverse range of applications. The blueglobe fire protection cable gland with its sealing insert made of T80 is available in sizes from M12 to M63 in both brass and stainless steel. The blueglobe TRI fire protection cable gland combines EMC protection with excellent RF screening attenuation values and has been successfully tested in accordance with the current fire protection standards EN 45545-2 and EN 45545-3. The T80 material for the sealing inserts meets the strict HL3 requirements of the EU standard for unrestricted use in trains. With its triangle spring, it makes 360° contact with the shielding braid, which means the blueglobe TRI fire protection cable gland sets high standards in terms of screening attenuation values. The blueglobe TRI is also optionally available with sealing inserts made of S55 silicone for high-temperature applications as well as with a long connection thread.

UNI Dicht fire protection cable gland

The UNI Dicht product range is characterised by features such as a high type of protection, operational reliability and durability. The appropriate sealing insert is selected depending on the application, thus providing maximum flexibility. The UNI Dicht fire protection cable gland is available in brass and stainless steel (with both standard and multiple sealing inserts).

Product portfolio fire protection cable glands

Downloads

|

Product information Fire protection cable glands

heute - 60: 2025-05-12

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2020-07-06 |

07/06/20 |

Cable gland |

1.5 MB | EN | Download |

FAQ

PFLITSCH fire protection cable glands are designed to be resistant for as long as possible in the event of a fire, so that it cannot penetrate through the gland and into the surrounding area. The materials are also designed and selected to emit a minimum of smoke and toxic gases.

In general, fire protection cable glands need to feature a high degree of tightness with the corresponding protection classes and effective strain relief. As they are also installed on the exteriors of trains, they need to be extremely weather-resistant and provide reliable protection from mechanical wear such as stone chipping and vibrations.

Depending on the application, effective EMC screening is also required and, last but not least, they need to be quick and inexpensive to install.

The requirements are so strict because in the event of a fire in a train, the impact on passengers must be kept as low as possible. The cable glands therefore also need to be part of the overall safety concept – just like the other installed components.

Each rail vehicle has a certain hazard class or hazard potential, depending on its specific field of application and design-related characteristics. The higher the hazard class, the stricter the fire protection requirements for the components and materials used.

Further information

Cable trunking

You’re also interested in the multitude of possibilities offered by our cable trunking solutions? Or are you looking for a concrete solution to a specific cable laying project? The Cable Trunking section provides an overview of all of our models and highlights their specific advantages and benefits.

Cable routing

Downloads

Are you looking for a comprehensive overview of PFLITSCH’s products and services? You can find the latest PFLITSCH catalogues and brochures in the Downloads section (PDF files).

Contact

You have questions about a product, would like to make an appointment for a one-to-one consultation or would like to experience our products live? Get in touch! We look forward to hearing from you.

Contact