PFLITSCH fire protection solutions –

when it comes to safety, we are right on track

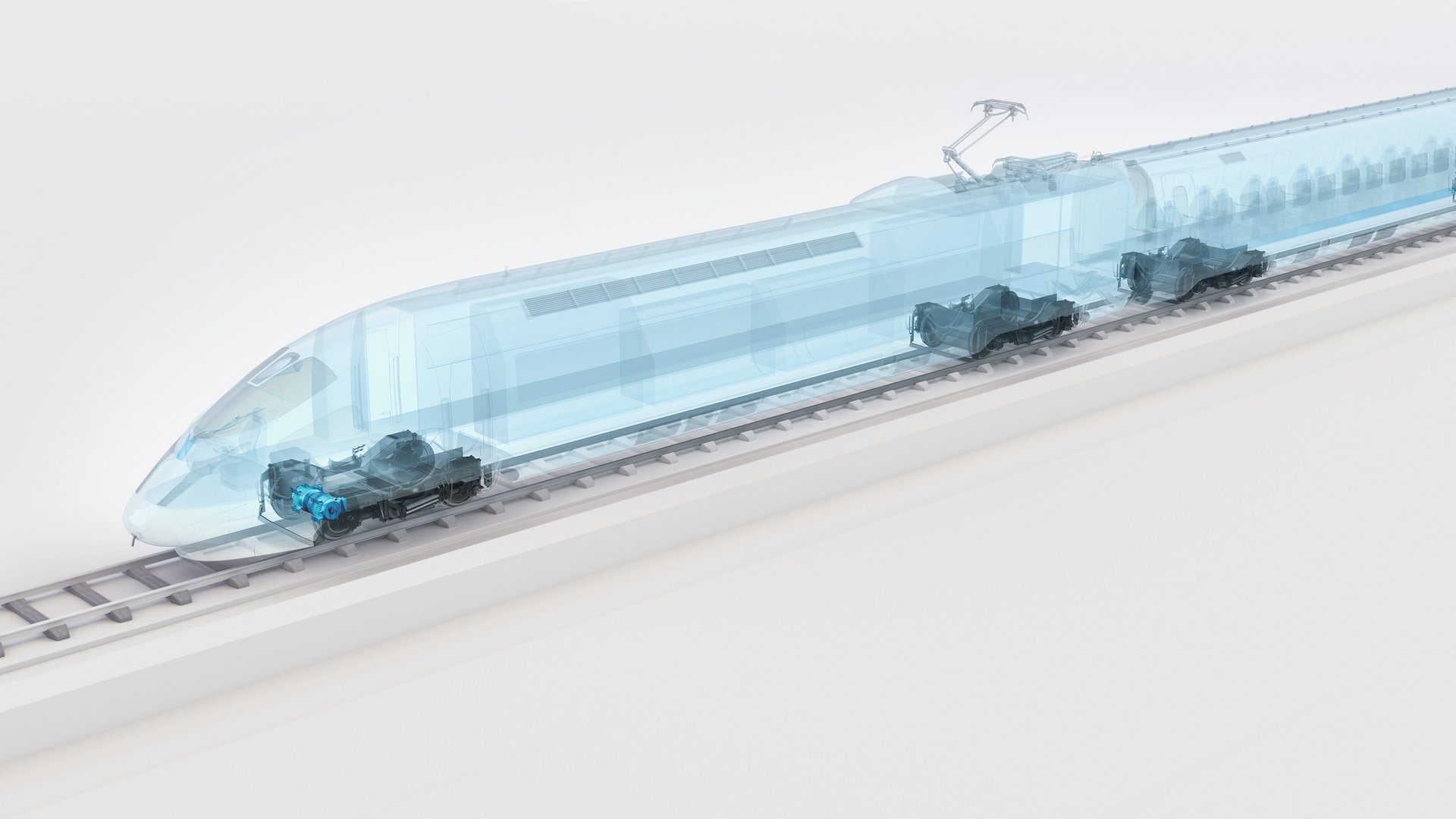

The railway industry has extremely strict requirements for its components, as safety is a top priority in the sector. Firstly, locomotives, carriages and the entire rail infrastructure all need to function in a reliably. Secondly, it is imperative to guarantee the best possible protection for passengers. Accordingly, the train safety concept is highly complex and applies to the entire railway vehicle. It includes interior and exterior installations and covers a wide variety of aspects, such as fire protection and electromagnetic compatibility (EMC).

Reliable protection – for every train

PFLITSCH offers you a coordinated range of certified cable glands and cable routing solutions for this purpose – and always has the right solution for every application. They meet the diverse and stringent fire protection requirements of the railway industry and guarantee you an outstanding level of reliability. Moreover, they have proven their efficiency in countless railway technology applications over a great many years. In other words, PFLITSCH solutions give you the certainty of always being on the safe side.

The advantages of our fire protection cable glands

Wide range of cable glands

Fire protection standards, including models with effective EMC shielding

High strain relief and tightness of seal in accordance with protection classes IP 68 and IP 69

For both interior and exterior use, extremely weather- and temperature-resistant

Protection from stone chipping and vibrations

Proven EMC cable glands for effective screening attenuation

Low total costs across the entire life cycle

Above-average durability and time- and cost-saving ease of installation

Typical applications in trains

Fire protection cable glands

At first glance, cable glands play no more than a secondary role in the overall safety concept of a railway vehicle. However, they are indispensable when it comes to ensuring reliable, seamless fire protection in trains, as the primary aim is that every component and all the materials used fundamentally contribute to either preventing a fire or limiting its spread and the resulting consequences. In view of the increasing level of automation in railway technology, not only certified fire protection but also effective EMC protection are becoming more important than ever.

Standards and certificates

Our products meet all the harmonised specifications and can be used worldwide for unrestricted interoperability without the need for additional testing. That’s why we have our products continuously tested and certified in accordance with current standards. In recent tests they obtained recertification and verified their performance ratings, some of which significantly exceed the test requirements. They also meet the most stringent HL2 and HL3 fire protection requirements in their relevant fields. In other words, PFLITSCH fire protection cable glands are state of the art and can be deployed in all types of trains – whether on the open track, in tunnels or at stations.

Flammability rating according to EN 45545

A number of norms and standards have been created to test the two essential criteria of fire protection, i.e. the control of the spread of smoke and fire and the containment of harmful smoke and gas development. Apart from the globally recognised EN 45545-2 and EN 45545-3 standards, which cover both areas, manufacturer- and association-specific standards such as the Bombardier standard SMP 800 and the US NFPA standard also play an important role.

EN 45545-2 for – Material testing

The fire protection requirements for cable glands depend firstly on where they are to be used in the train and are divided into interior (R22) and exterior (R23) use categories. Secondly, the hazard level (HL) of the train is also an important factor, which is determined by the operation category and the design category. The material testing itself verifies compliance with the threshold values for oxygen content, flue gas density and toxicity. The focus here is mainly on sealing inserts made of various plastics, as metals do not usually catch fire. PFLITSCH offers sealing inserts that comply with the standards required for every conceivable application .

EN 45545-3 – Fire resistance of fire barriers test

Complete cable glands undergo the “Integrity” fire resistance test. In our case, that means the UNI Dicht and blueglobe cable glands as well as the blind plugs. The demanding E30 fire resistance class was achieved in the test. In concrete terms, this means the cable glands are fire-resistant for 30 minutes, which is twice as long as required in accordance with EN 45545-3 (E15 = 15 minutes).

Bombardier standard SMP 800

The French Bombardier standard SMP 800 is designed to test the emission of toxic vapours by the sealing inserts of cable glands in the event of fire. Both PFLITSCH fire protection sealing inserts made of TPE and silicone are well below the limit values.

NFPA standard

The US NFPA standard is also important. The tests examine properties such as heat development and visible smoke release rates. We had these properties tested for our fire protection sealing inserts made of TPE and silicone by the Currenta testing laboratory in Leverkusen: both passed with flying colours.

Cable routing

Our product range also includes cable routing solutions. Cables used for transmitting data, signals and electricity need to be routed on both the inside and the outside of the train. To install them both safely and with sufficient protection, PFLITSCH offers its tried-and-tested Wire-tray Trunking system, which is ideally suited for use in the railway industry because of its robust yet lightweight design. As a customised solution with a partition wall already welded in, it also ensures that cables are clearly routed.

The advantages of our Wire-tray Trunking system

- Robust PFLITSCH Wire-tray Trunking provides ideal protection

- Customised solutions (e.g. Wire-tray Trunking with welded partition wall/for the customer Stadler)

- Wire-tray Trunking available in a variety of materials and shapes for maximum cable routing flexibility

- PFLITSCH component assembly service for precisely fitting, ready-to-install solutions that guarantee an efficient process

Downloads

|

Product information Fire protection cable glands

heute - 60: 2025-05-19

documentCreationDateTime: 2024-05-08 fileUploadDateTime: 2020-07-06 |

07/06/20 |

Cable gland |

1.5 MB | EN | Download |

![[Translate to Englisch (US):] [Translate to Englisch (US):]](/fileadmin/_processed_/a/e/csm_AAB_Rendering_Applikation_Bahn_Bremsensteuerung_28f208cb76.jpg)

![[Translate to Englisch (US):] [Translate to Englisch (US):]](/fileadmin/_processed_/2/c/csm_AAB_Rendering_Applikation_Bahn_Radsensoren_9b34c22ffd.jpg)

![[Translate to Englisch (US):] [Translate to Englisch (US):]](/fileadmin/_processed_/2/6/csm_AAB_Rendering_Applikation_Bahn_Klimaanlage_704b567b72.jpg)

![[Translate to Englisch (US):] [Translate to Englisch (US):]](/fileadmin/_processed_/8/4/csm_AAB_Rendering_Applikation_Bahn_Stromabnehmer_c2546ee789.jpg)

![[Translate to Englisch (US):] [Translate to Englisch (US):]](/fileadmin/_processed_/6/0/csm_AAB_Rendering_Applikation_Bahn_Umrichter_d14d88bebd.jpg)

![[Translate to Englisch (US):] [Translate to Englisch (US):]](/fileadmin/_processed_/f/d/csm_AAB_Rendering_Applikation_Bahn_Wagenuebergang_9ba8ff46ec.jpg)